Gas Chromatography-Mass Spectrometry (GC/MS) is a powerful analytical technique used in various scientific fields, including chemistry, environmental analysis, and forensics. To ensure accurate and reliable results, it is essential to maintain the integrity of your GC/MS system. One common issue that can affect the performance of your instrument is leaks. Identifying leaks early on is crucial for preventing data inaccuracies and instrument downtime. In this blog post, we’ll guide you through the process of identifying leaks in your GC/MS system to optimize its efficiency and overall performance.

Regular Visual Inspections

Performing routine visual inspections is the first step in leak detection. Examine the entire system, including gas lines, tubing, fittings, and septa, for any signs of wear, damage, or corrosion. Leaks can often result from worn-out or improperly sealed components, so a thorough visual inspection can help identify potential issues.

Utilize Leak Detection Tools

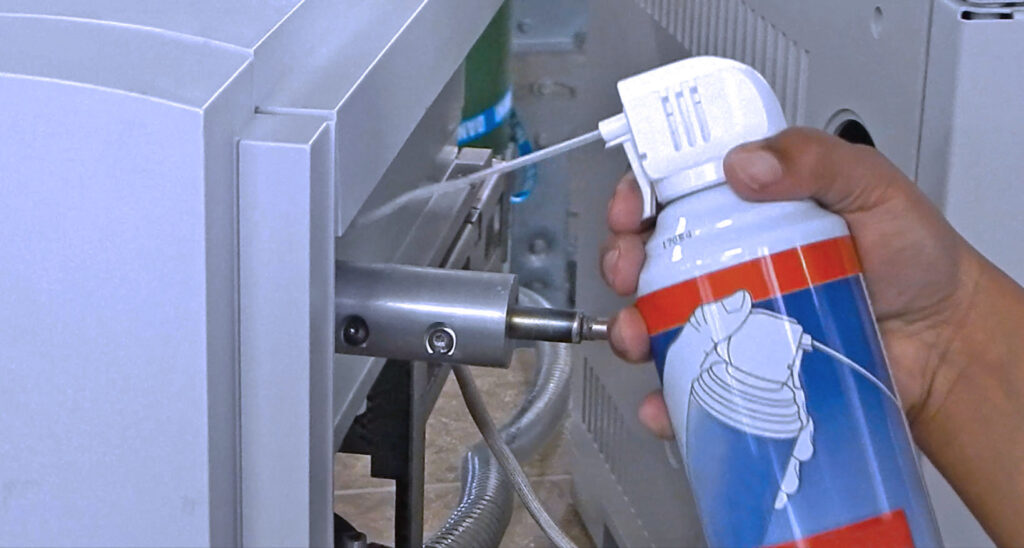

In addition to visual inspections, modern GC/MS systems come equipped with leak detection tools. These tools use various methods like pressure decay, helium leak detection, or electronic leak detection to identify leaks more accurately. Regularly use these built-in features as part of your system’s maintenance to catch leaks early on and prevent larger problems down the road.

Conduct Leak Tests

Periodically conduct leak tests using helium or another suitable tracer gas. This process involves introducing the tracer gas into the system and monitoring for any gas escaping. Helium leak detectors are highly sensitive and can identify even the smallest leaks, helping you pinpoint the exact location of the issue.

Check Carrier Gas Flow Rates

Inconsistent or unusually low carrier gas flow rates can be indicative of a leak. Regularly monitor and calibrate the flow rates to ensure they are within the expected range. Drastic fluctuations in flow rates may suggest a leak that needs immediate attention.

Analyze Baseline Noise

Baseline noise in the mass spectrometer can also indicate potential leaks. Unexplained increases in baseline noise may be a result of contamination due to leaks. Regularly monitor the baseline noise levels and investigate any significant deviations.

Seek Professional Maintenance

While routine inspections and leak tests are essential, professional maintenance by qualified technicians is equally important. Periodically schedule maintenance with an authorized service provider to ensure the system is thoroughly checked, cleaned, and any potential issues are addressed promptly.

Identifying leaks in your GC/MS system is crucial for maintaining data integrity and ensuring accurate results in your analytical work. By staying proactive and seeking professional maintenance, you can minimize instrument downtime, save costs on repairs, and improve the overall efficiency of your GC/MS system.

In summary, when it comes to the service and preventative maintenance of your GC/MS system, Conquer Scientific stands as your trusted partner. Their unmatched proficiency and commitment to customer support make them the ideal choice to ensure your GC/MS system continues to deliver accurate and precise results for your analytical needs.